Key Criteria for Selecting High-Voltage Glass Insulators

What are the factors to consider when selecting high-voltage glass insulators?

It is important to consider several factors to ensure their suitability and optimal performance in a specific electrical system.

These factors include the required mechanical strength, the line voltage level, local environmental conditions, expected electrical load, and maintenance requirements.

Additionally, compatibility with other system components and adherence to safety and quality standards are also important considerations during the selection process.

- Mechanical strength

- Line voltage

- Local environmental conditions

- Maintenance requirements

What are the main parameters that define each model of glass insulator?

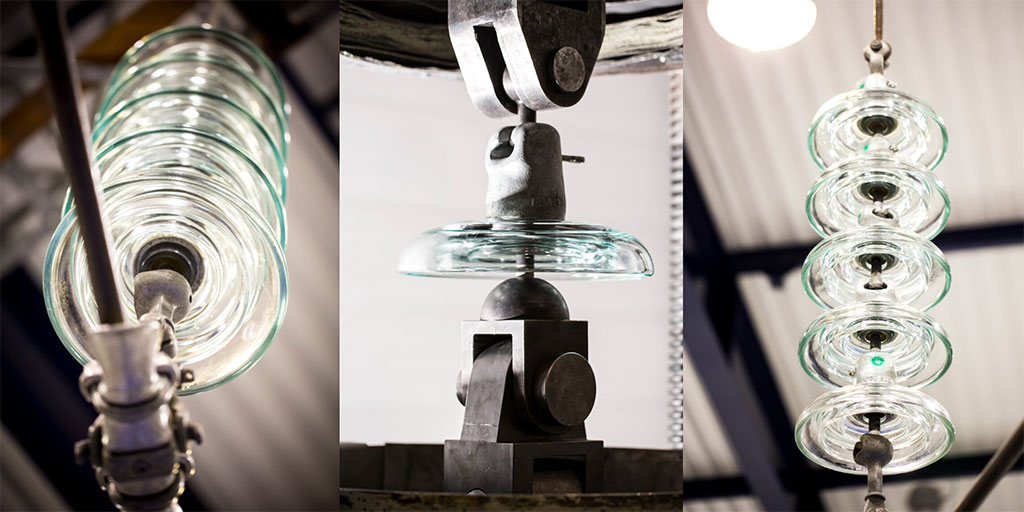

Each insulator model is defined by a series of parameters defined by the manufacturer and can be seen in the catalogue or on the drawings of every insulator, which must comply with at least the minimum or maximum values required by the different applicable standards.

The main parameters include:

- The Mechanical → Mechanical breaking load

- The Dimensional → Coupling standard, diameter, creepage distance, and pitch

- The Geometric → Shape of the insulator profile

- The Electrical → Electric withstand voltages for puncture, dry and wet power frequency, and lightning impulse withstand voltages

For each power line project, the required chain parameters must be properly calculated, and the most appropriate insulators must be chosen for each case.

Upcoming Industry Events and Participation in 2026

The next year promises to be a year of strong international presence for La Granja Insulators, as we continue strengthening our relationships with partners, customers, and key stakeholders across the global energy sector.

We will take part in several major industry events that bring together manufacturers, utilities, engineers, and technical experts shaping the future of the power and renewable energy landscape. Below is a first look at the key events where we will be present in 2026:

Middle East Energy 2026 – Dubai World Trade Centre

We will once again participate in Middle East Energy (MEE) 2026, one of the most influential energy exhibitions in the world. La Granja Insulators will have its own booth at the Dubai World Trade Centre (booth number to be confirmed).

Our delegation this year will include Bruno Portellano, Miguel Ángel Morales, Elena García, and Mikel Campos, who will be available to meet with customers, partners, and industry professionals seeking insights into our solutions and ongoing developments.

CIGRÉ 2026

As in previous editions, La Granja Insulators will take part again in CIGRÉ 2026, one of the world’s most important gatherings of the electric power systems community.

We will host our own booth (number to be announced), which will remain active throughout the six-day event. Given the scale of the conference and the diversity of its sessions, several members of our team will rotate attendance to ensure continuous support, engagement, and availability for visitors.

CIGRÉ continues to be an essential forum for international cooperation, knowledge exchange, and discussion of the sector’s strategic challenges.

2026 IEEE International Power and Renewable Energy Conference

At the IEEE International Power and Renewable Energy Conference 2026, we will be supporting our North American partner, Hubbell Power Systems, which will host their own booth during the event.

Our presence will focus on reinforcing our collaboration and participating in discussions related to innovation, renewable integration, and power system reliability.

Looking Ahead

These events represent valuable opportunities to strengthen our global positioning, exchange knowledge with industry leaders, and present the continued evolution of our products and technologies.

In the coming months, we will share additional details, including booth numbers, agendas, and activities planned for each event. We look forward to meeting many of you there!

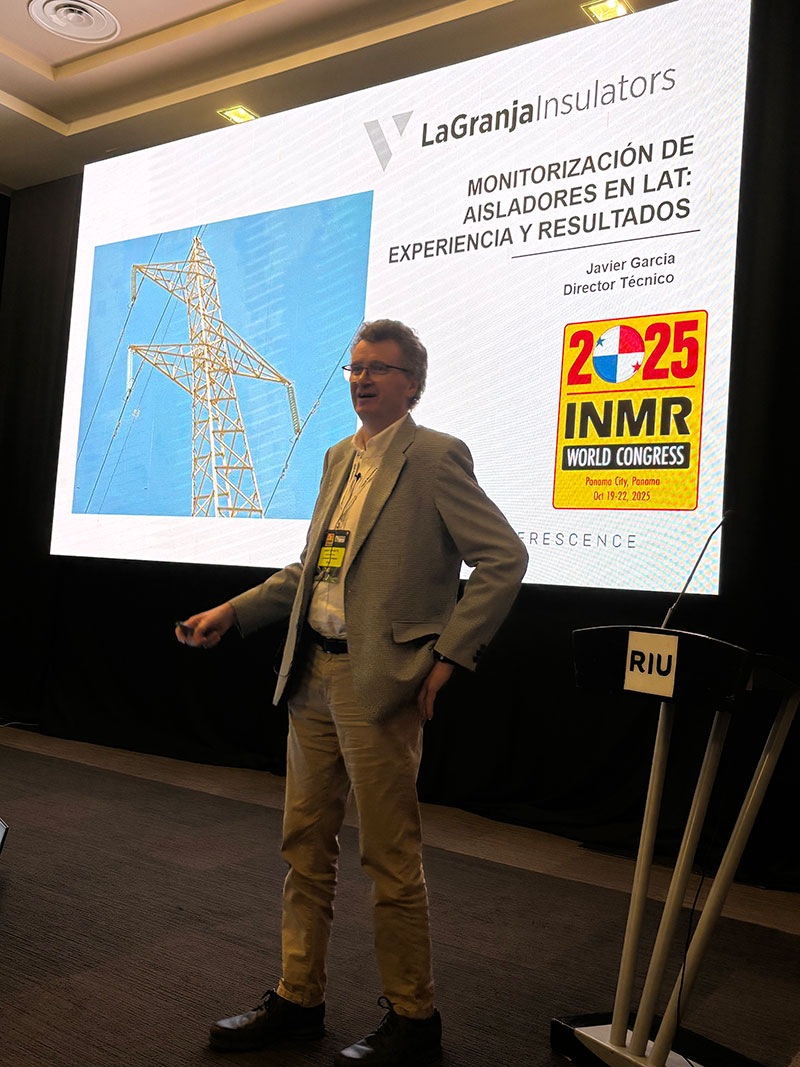

INMR Congress 2025 Panama

INMR, derived from the acronym “INSULATORS DAY AND MARKET REPORT”, is an international organization dedicated to promoting the exchange of technical knowledge in the field of high-voltage insulators: https://www.inmr.com

Every two years, INMR hosts a world congress where electric utilities, installers, manufacturers, engineering firms, and laboratories present technical papers covering various areas of high-voltage electrical insulation. The congress also features an exhibition hall with stands from industry companies:

https://www.inmrworldcongress.com

From October 19 to 22, 2025, Panama hosted this year’s edition of the INMR International Symposium.

Verescence – La Granja Insulators participated in the congress with its own stand, welcoming and engaging with companies from across the electrical sector.

Representing La Granja Insulators in the congress were:

- Bruno Portellano (General Director)

- Mikel Campos (Insulators Sales Director)

- Javier García (Insulators Technical Director)

- Miguel Ángel Morales (Area Manager)

During the event, Javier García delivered a presentation titled: “Monitoring of Insulators in High Voltage Transmission Lines: Experience and Results.”

His presentation highlighted the significant progress achieved by our Technical Department in monitoring leakage current, environmental parameters, and pollution levels. Through the application of AI, these measurements make it possible to estimate the behaviour of insulator strings, an approach that can lead to substantial reductions in maintenance costs for electric utilities.

For the first time in the history of the congress, presentations were delivered in both English and Spanish to facilitate broader participation from the South American market.

We’re grateful to have once again taken part in this event, a global meeting point for professionals shaping the future of the insulator industry.

Cigré Canada 2025

CIGRE, the International Council on Large Electric Systems, is a global collaborative community dedicated to the development and exchange of technical knowledge related to electric power systems: https://www.cigre.org/

It brings together thousands of professionals from more than 90 countries and over 1,250 member organizations, making it one of the most influential technical communities in the sector. CIGRE also leads one of the world’s most respected knowledge development programs, spanning 16 domains that cover every core aspect of power system engineering. Across these domains, more than 250 Working Groups draw on practical experience and scientific expertise to address both current and emerging challenges facing the industry.

From September 29th to October 3rd, La Granja Insulators, together with our North American partner Hubbell Power Systems, participated in the CIGRE International Symposium in Montreal, Canada, exhibiting at booth #623.

This edition of the symposium brought together key global, regional, and local stakeholders from across the electric power systems sector, including industry leaders, grid operators, manufacturers, engineers, researchers, policymakers, regulators, and academic experts. The event provided a premier forum for examining the latest trends shaping the evolving energy landscape, exchanging technical insights, sharing research advancements, and discussing the strategic directions that will define the future of the industry.

In addition to our presence, La Granja Insulators contributed to the technical agenda with the presentation of our paper: “Optimizing Maintenance Operations and Insulation Selection through Insulator Monitoring in Polluted Environments.”

Insulators Day

El pasado 28 de octubre celebramos en el restaurante Zibá, en Segovia, una nueva edición del Insulators Day, una jornada muy especial para el equipo de La Granja Insulators. Esta fue una ocasión para reunirnos y fortalecer los lazos entre los diferentes departamentos que forman parte del proceso de fabricación y venta de nuestros aisladores de vidrio.

La jornada comenzó a las 10:30 con un café de bienvenida. A las 11:00, dieron inicio las presentaciones de Bruno Portellano, Mikel Campos, Javier García, Elena García, Jesús Oliver y Federico Ramos, quienes compartieron sobre los avances, logros y próximos desafíos de la compañía.

El encuentro concluyó a las 14:00 con un almuerzo en el que todo el equipo pudo disfrutar de un momento de convivencia.

Este Insulators Day 2025 volvió a recordarnos que detrás de cada proyecto hay un equipo comprometido.

Press Day: Visita de Medios A La Granja Insulators

El miércoles 29 de octubre recibimos en nuestra fábrica a periodistas de Expansión, EL ESPAÑOL, Agencia EFE, Revista Energética XXI y El Periódico de la Energía.

Durante esas semanas, diversos medios publicaron nuevos reportajes destacando el trabajo que realizamos desde nuestra planta en La Granja de San Ildefonso, así como los avances alcanzados recientemente, entre ellos la inversión destinada a modernizar nuestras instalaciones y reforzar nuestra capacidad productiva.

Durante la visita, los profesionales pudieron conocer de primera mano cómo trabajamos en La Granja Insulators: nuestros procesos de producción, nuestra forma de afrontar los retos del sector y, sobre todo, el talento humano que impulsa cada una de nuestras áreas.

Agradecemos sinceramente su tiempo, su interés y la oportunidad de compartir con ellos una jornada de conversación abierta sobre el presente y el futuro de las redes eléctricas.

Mención especial por su visita a:

- Beatriz Treceño Torío – Expansión

- Laura Ojea – EL ESPAÑOL

- Karina Doy – Agencia EFE

- Víctor Delgado Serrano – Revista Energética XXI

- Sandra Acosta Ruiz – El Periódico de la Energía

Acceso a los artículos, en versión digital, publicados:

- Solo Industria: https://soloindustria.com/la-granja-insulators-verescence-refuerza-su-liderazgo-global-con-una-inversion-de-16-millones-en-su-planta-de-segovia/

- Expansión: https://www.expansion.com/economia-sostenible/2025/11/05/690a0e91468aeb3e7f8b45c3.html

- El Español: https://www.elespanol.com/invertia/empresas/energia/20251102/granja-insulator-vidrio-segovia-lider-construccion-redes-electricas-unidos-arabia-saudi/1003743995131_0.html

- Energética: https://energetica21.com/noticia/granja-insulators-acelera-expansion-global-desde-segovia-mas-produccion-compromiso-climatico

- El Periódico de la Energía: https://elperiodicodelaenergia.com/aisladores-electricos-de-vidrio-made-in-spain-la-joya-industrial-en-la-granja-de-san-ildefonso-que-refuerza-las-redes-electricas-en-todo-el-mundo/

- Castilla y León Económica: https://www.castillayleoneconomica.es/verescence-invierte-16-millones-planta-segovia-aisladores-vidrio/

- El Economista: https://www.eleconomista.es/energia/noticias/13637503/11/25/la-granja-insulators-aumenta-un-34-su-capacidad-productiva-tras-una-inversion-de-16-millones-en-su-planta-de-segovia.html

La Granja Insulators acelera su expansión global desde Segovia con más producción y compromiso climático

La planta de la compañía española, especializada en aisladores de vidrio para redes eléctricas de alta tensión, incrementa un 34% su capacidad productiva para responder a la creciente demanda internacional.

La Granja Insulators(que forma parte del grupo francésVerescence)ha completado una importante fase de expansión en su planta deLa Granja (Segovia), donde produceaisladores de vidrio para redes eléctricas de alta tensión. Estos elementos son muy importantes, ya que el 90% de los problemas una vez puesta en marcha una instalación se producen en ellos. Los fabricantes son pocos y las barreras de entrada al sector, muy grandes por el necesarioknow-howy las enormes inversiones iniciales que requieren. Es en ese nicho donde La Granja Insulators se ha erigido como socio tecnológico para utilities, ingenierías y fabricantes de equipos eléctricos.

La empresa ha invertido16 millones de eurosen la modernización de sus instalaciones, lo que le permitiráaumentar un 34% su capacidad productivahasta alcanzarlos 4 millones de aisladores anuales. Con ello, busca dar respuesta a lacreciente demanda internacionalen un contexto marcado por la electrificación, el refuerzo de las redes y la necesidad de mejorar la fiabilidad de los sistemas energéticos.

Durante una visita a la fábrica, en la que estuvo presente laRevista Energética,la dirección de la compañía explicó que esta expansión “consolida a La Granja Insulators comoreferente europeo en soluciones para transmisión y distribución eléctrica”.El contexto geopolítico está influyendo en el mercado y hace que este tienda a priorizar lafabricación cercanay laindependencia industrial.En los últimos años, el principal fabricante ruso se ha visto aislado tras la guerra, mientras que las empresas chinas tienen muy difícil vender sus productos a los países occidentales.

Con la suma de todos estos factores, Verescence La Granja cuenta ya con más de 525 empleados a los que sumar sus proveedores de servicios externos. Para la unidad de negocio de aisladores trabajan 160 empleados que exportanel 98% de su producción, principalmente aEuropa, Norteamérica y Oriente Medio. Además, este año han vivido un cambio en la propiedad, ya que en la primera mitad de 2025 han entrado como accionistas en Verescence dos fondos de inversión portugueses: Movendo Capital y Draycott.

El manager general de la empresa, Bruno Portellano, destacó que el objetivo es “reforzar el valor del ‘Made in Spain’ y responder al auge de las redes eléctricas con una oferta competitiva y sostenible”. Según explicó, la compañía mantiene plantas operativas en España, Francia, Corea del Sur y Estados Unidos, lo que le permite adaptarse con rapidez a las necesidades de los clientes en distintos mercados y garantizar su resiliencia industrial.

Por su parte, Mikel Campos, director global de Ventas y Marketing, señaló que el mercado mundial de aisladores “crecerá alrededor de un 7% anual” en los próximos años, impulsado por la renovación de infraestructuras, la electrificación del transporte y la industria, y las nuevas interconexiones internacionales. En este entorno, los aisladores de vidrio ganan terreno frente a los de porcelana por su mayor durabilidad y facilidad de mantenimiento, y representan ya cerca del 40% de la cuota de mercado global, prácticamente empatados con los de composite.

Tal es la demanda que la fábrica de La Granja no descansa y sus trabajadores cubren por turnos las 24 horas del día de los 365 días del año con encargos asegurados hasta 2027. En la factoría se han desarrollado tecnologías propias como SILGLASS, un recubrimiento de silicona RTV patentado que mejora el comportamiento de los aisladores en entornos con alta contaminación o condiciones climáticas extremas. Este avance permite reducir pérdidas eléctricas, minimizar limpiezas y prolongar la vida útil de las instalaciones, factores clave para garantizar la eficiencia de las redes de transmisión.

La producción de aisladores se inicia en 1932, habiéndose comenzado la fabricación de vidrío con la fundación de la Real Fábrica de Cristal en 1760. Hoy en día, los equipos de la fábrica segoviana diseñan, fabrican y validan aisladores para redes de hasta 765 kV, con más de 100 millones de unidades instaladas en más de 120 países. La empresa colabora además con operadoras eléctricas y organismos internacionales en el desarrollo de estándares y proyectos de innovación.

Durante la visita, Javier García, director técnico de Aisladores, subrayó la importancia de la innovación aplicada al rendimiento y mantenimiento de las redes eléctricas. Explicó que el ensuciamiento de los aisladores puede generar corrientes de fuga y descargas superficiales, y que por ello la compañía trabaja en recubrimientos avanzados y soluciones predictivas. “Nuestro objetivo es que las redes sean más seguras y eficientes; estamos desarrollando herramientas de inteligencia artificial para determinar cuándo y cómo limpiar los aisladores, evitando intervenciones innecesarias y optimizando recursos”, apuntó.

Valor medioambiental y social

El compromiso medioambiental constituye otro pilar en el crecimiento de La Granja Insulators. La empresa se sitúa en el 1% de las mejor valoradas por EcoVadis, cuenta con un plan de reducción de emisiones validado por SBTi y se ha marcado como objetivo disminuir un 64% sus emisiones de CO2 para 2034 y alcanzar la neutralidad climática en 2050. Entre las medidas ya implantadas destacan la recuperación del 98% del agua utilizada en los procesos productivos, la reincorporación del 92% del vidrio reciclado, la reducción del 19% de las emisiones directas y la recuperación del 91% de los residuos generados.

La empresa planea también renovar su horno principal en 2031, con un modelo híbrido (75% eléctrico y 25% a gas), que reducirá de forma significativa el consumo energético y las emisiones asociadas a la fundición del vidrio.

En el ámbito económico y social, la planta mantiene una estrecha vinculación con su entorno. Su actividad industrial genera empleo directo e indirecto en la comarca segoviana y contribuye a la estabilidad de un territorio con fuerte tradición manufacturera. En palabras de su dirección, “la fábrica y el municipio de La Granja comparten historia y futuro”.

Fuente: energetica21.com

Aisladores eléctricos de vidrio ‘made in Spain’

La Granja Insulators tiene ya instaladas más 120 millones de unidades en redes eléctricas de todo el mundo, desde Canadá hasta Arabia Saudí

En pleno corazón de la Sierra de Guadarrama, donde el aire frío baja del puerto de Navacerrada y el tiempo parece detenerse entre los jardines del Palacio Real, late una de las fábricas más singulares de España: La Granja Insulators, un gigante invisible que sostiene, literalmente, la electricidad del planeta. Desde este rincón segoviano, un pueblo de apenas cinco mil habitantes, se fabrican los aisladores eléctricos de vidrio que garantizan la estabilidad de las redes de alta tensión en más de 120 países.

“Queremos que el mundo sepa que el made in Spain también significa tecnología, precisión e innovación”, afirma Bruno Portellano, director general de La Granja Insulators. Su voz mezcla orgullo y convicción. No es para menos: la empresa, heredera de la histórica Real Fábrica de Cristales fundada por Carlos III en el siglo XVIII, es hoy la única que cuenta con una planta que integra todos los procesos productivos del vidrio, ensamblaje y siliconado de aisladores, así como laboratorio.

Un legado centenario convertido en motor tecnológico

La historia industrial de La Granja comenzó en 1932, cuando se produjo el primer aislador de vidrio para el sector telefónico. En 1959, la compañía —entonces bajo el paraguas de Saint-Gobain— dio el salto al sector energético, fabricando aisladores de suspensión para líneas de alta tensión. Desde entonces, su evolución ha sido constante: innovación, automatización y sostenibilidad son las claves de su crecimiento.

En 2010, la empresa registró la patente SILGLASS, un recubrimiento de silicona que mejora el comportamiento eléctrico en zonas de alta contaminación o humedad. Y en 2022 lanzó Xpertise Smart Insulation, un software basado en inteligencia artificial capaz de predecir cuándo realizar mantenimientos en las líneas eléctricas. “El aislador puede representar solo el 3% del coste de una infraestructura eléctrica, pero causa el 90% de los problemas si falla”, recuerda Portellano.

Hoy, la planta segoviana produce más de 4 millones de aisladores al año, con capacidad para soportar hasta 765.000 voltios. En servicio hay ya más de 120 millones de unidades fabricadas en La Granja, instaladas en redes eléctricas de todo el mundo, desde Canadá hasta Arabia Saudí.

Un mercado global en expansión

El mercado mundial de los aisladores eléctricos, valorado en 585 millones de euros, vive un auge sin precedentes. “Estamos en un momento clave”, explica Mikel Campos, director de ventas y marketing de la compañía. “La renovación de líneas eléctricas en Europa y Estados Unidos, el auge de las energías renovables y el crecimiento de países en desarrollo están disparando la demanda”.

Los aisladores de vidrio están ganando terreno a los de porcelana y composite: hace una década representaban el 15% del mercado; hoy rozan el 40%. En un sector donde la demanda supera la capacidad de producción, La Granja Insulators se sitúa entre los dos únicos fabricantes occidentales relevantes, junto a la francesa Sediver. Su cuota actual es del 11%, con un ambicioso objetivo: alcanzar los 90 millones de euros en ventas en 2030.

El Oriente Medio es actualmente su principal mercado, seguido de Europa y Norteamérica. Arabia Saudí, en particular, ha experimentado un crecimiento “brutal”, impulsado por sus megaproyectos energéticos. La empresa también planea abrir mini plantas de ensamblaje en diferentes zonas estratégicas.

Innovación y sostenibilidad: el nuevo eje de la fábrica

La compañía ha invertido más de 16 millones de euros desde 2020 para automatizar procesos y mejorar la eficiencia, incrementando en un 24% su capacidad productiva. En paralelo, ha reducido un 19% sus emisiones de CO2 desde 2016 y se ha comprometido a recortar un 64% sus emisiones de alcance 1 y 2 para 2034, dentro de su plan de descarbonización certificado por la iniciativa internacional SBTi.

Fuente: elperiodicodelaenergia.com

La Granja Insulators en RTVE: un recorrido por nuestra fábrica

El programa “Aquí hay trabajo” de RTVE ha visitado recientemente nuestras instalaciones en La Granja Insulators, mostrando en un completo reportaje el día a día de nuestra fábrica en la Granja de San Ildefonso (Segovia).

Durante este reportaje, los espectadores pueden conocer de primera mano qué es un aislador de vidrio y cómo se desarrolla todo el proceso de producción: desde el diseño y la fabricación, hasta el control de calidad, el ensamblaje, los ensayos de laboratorio y el empaquetado final para su distribución internacional.

Uno de los aspectos destacados es el riguroso protocolo de seguridad que sigue nuestro equipo antes de acceder a la zona de producción: chaleco reflectante, gafas de protección y tapones auditivos, garantizando así un entorno de trabajo seguro en todo momento.

El reportaje también pone en valor la experiencia y compromiso de nuestros más de 700 profesionales, cuya pasión y entusiasmo hacen posible que nuestros aisladores lleguen hoy a más de 120 países de todo el mundo.

Además, expertos como Jesús Oliver, Raúl Casado, José Carlos Ledo, Fausto de Lucas y Javier Sánchez comparten su visión sobre los procesos, la innovación y la importancia de mantener la excelencia en cada etapa de la producción.

Para ver el reportaje completo en RTVE aquí: https://www.rtve.es/play/videos/aqui-hay-trabajo/fabrica-aisladores/16748976/

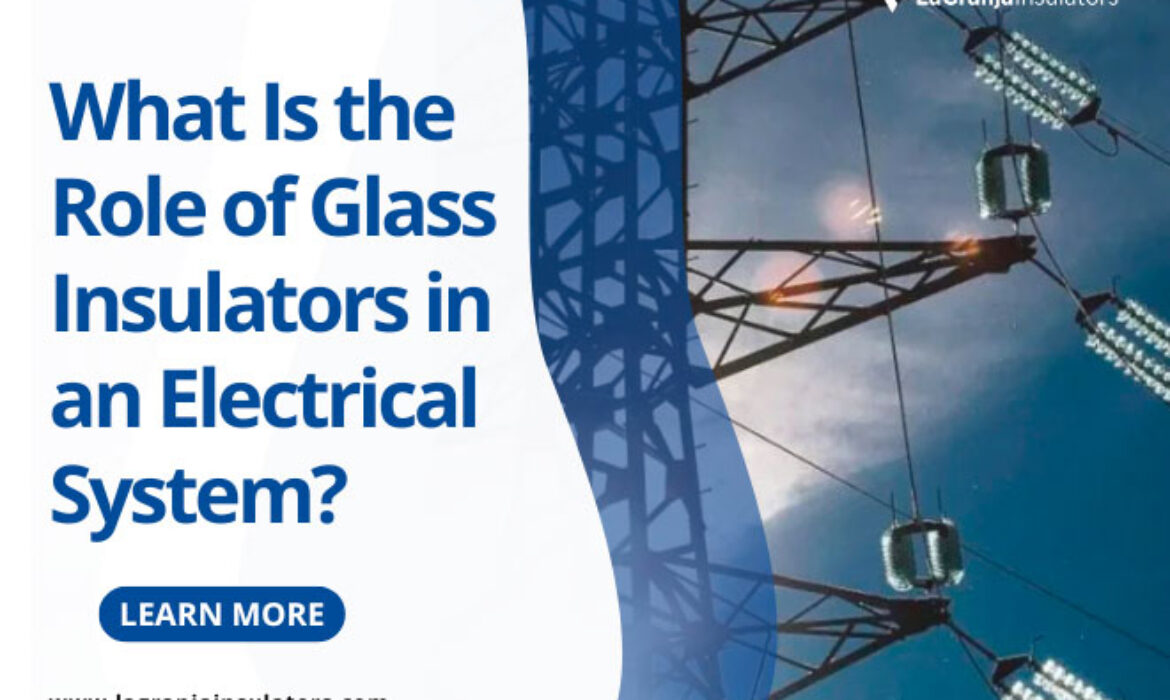

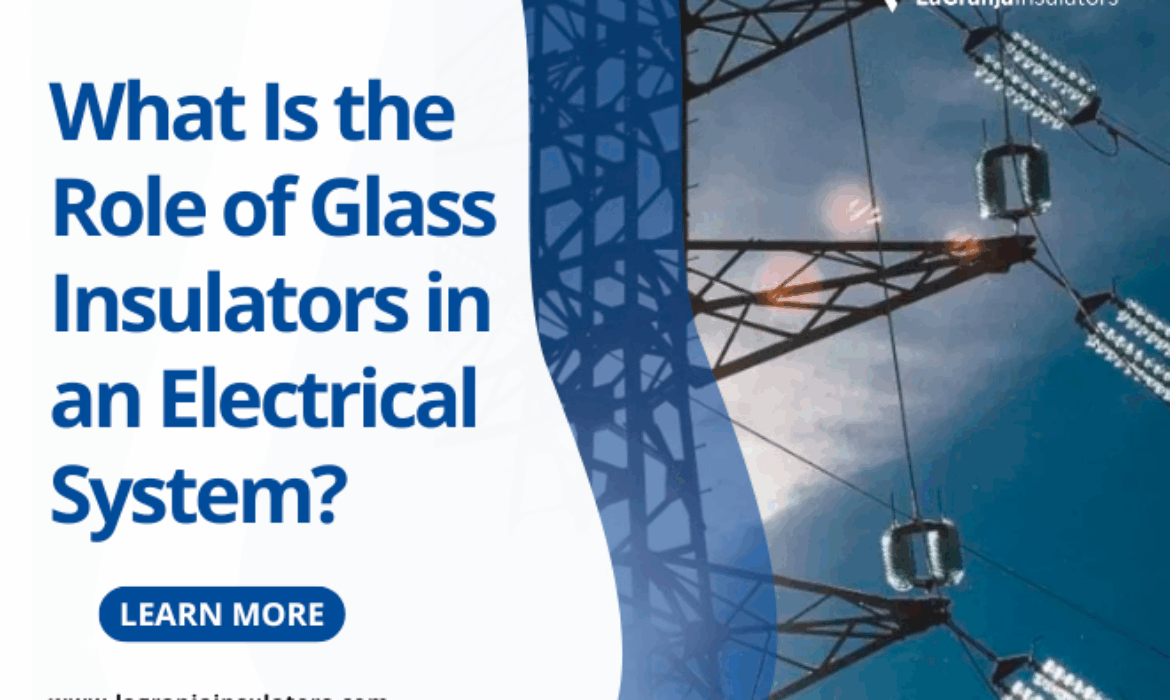

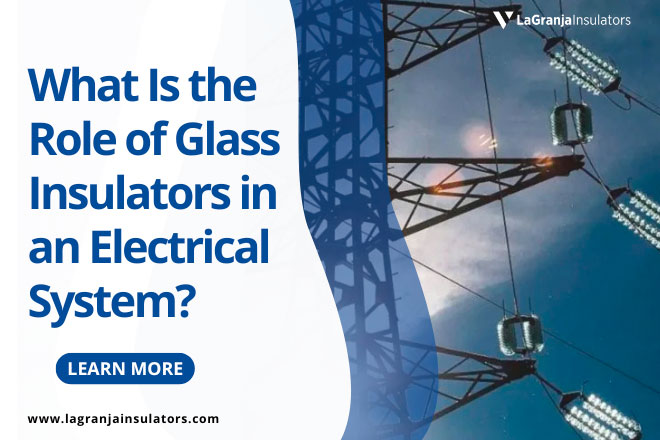

What Is the Role of Glass Insulators in an Electrical System?

Why this critical component is key to safe and reliable power transmission.

In the world of energy, every component matters. High-voltage glass insulators, though often overlooked, play a crucial role in ensuring the safety and efficiency of modern electrical systems.

They act as insulating barriers between electrical conductors and supporting structures, preventing short circuits and electrical discharges that could cause power supply interruptions or equipment damage.

In addition, they help maintain system stability by preventing current leakage and ensuring a uniform distribution of electrical load.

Key Takeaways

- Glass insulators prevent short circuits and electrical discharges.

- They maintain the stability of the electrical system.

- Help avoid any interruptions in power supply.